How to Choose the Best Preprinted Labels for Your Needs?

In the realm of packaging and organization, choosing the right preprinted labels can make a significant difference. Sarah Thompson, a leading expert in label production, emphasizes, "The right label can transform how we perceive information." This insight highlights the value of well-chosen preprinted labels in our daily tasks.

When considering preprinted labels, it’s essential to evaluate your specific needs. Different industries require unique labeling solutions. Whether for inventory, shipping, or personal use, clarity and design play vital roles. Labels must convey information effectively. Yet, many overlook details that matter, which can lead to confusion.

Visual appeal also matters. A label that stands out can improve efficiency. However, not all designs connect with the audience. It’s crucial to reflect on what works for you. What may seem appealing at first glance might falter in practicality. Thus, approaching the selection of preprinted labels with thoughtfulness is key.

Factors to Consider When Choosing Preprinted Labels

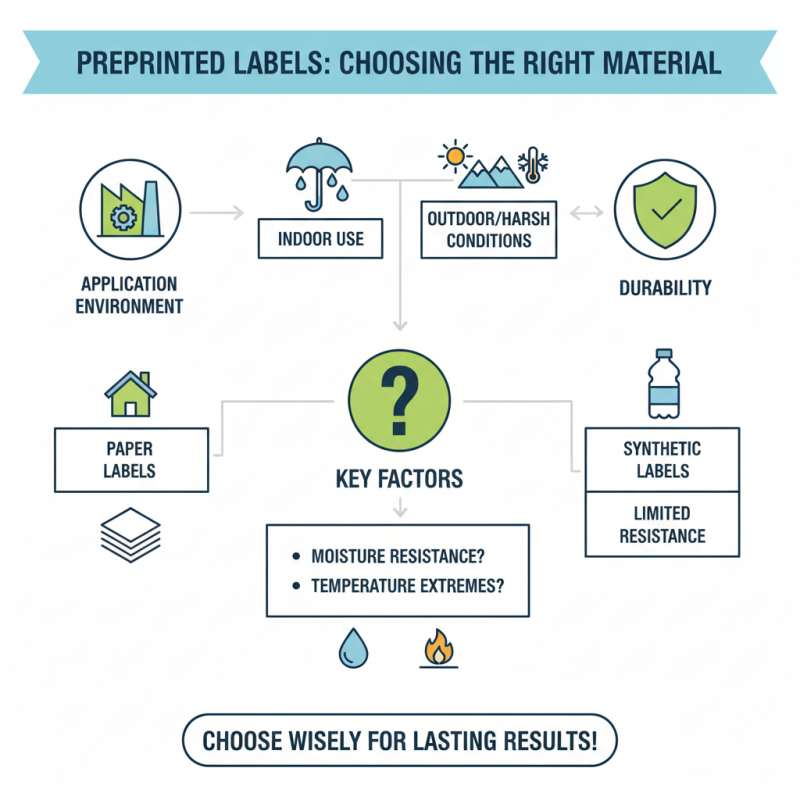

Choosing the right preprinted labels can be challenging. A key factor to consider is the label material. Different materials serve different purposes. Paper labels may be suitable for indoor use, while synthetic options resist moisture. Think about where the labels will be applied. Will they be exposed to water or extreme temperatures? These conditions can impact durability.

Another important factor is the design of the label. Clear and concise fonts aid readability. Colors matter too; they should match the overall branding. However, it is crucial not to overdo it with bright colors. A cluttered design can confuse the message. Make sure the label communicates essential information effectively.

Consider the size of the label as well. If the label is too small, details might get overlooked. On the flip side, an oversized label can seem out of place. Take time to measure the application area before deciding. These seemingly small choices can have a big impact on your labeling success. Reflect on these aspects carefully to ensure your labels meet your specific needs.

Understanding Different Types of Preprinted Labels Available

Preprinted labels come in various types, each serving different purposes. For example, shipping labels are essential for businesses. They help ensure packages reach their destinations. However, sometimes these labels can become smudged or torn, leading to delays. In such cases, having a backup plan is important.

Another type is product labels, often used in retail. These labels provide information about the items. They can include barcodes, prices, and ingredients. Yet, some consumers find them difficult to read. Poor font choices can create confusion. Choosing the right size and material can improve clarity.

Warning labels are crucial for safety. They alert users about potential hazards. Yet, if these labels are too small or poorly placed, they might go unnoticed. It’s vital to consider visibility when designing them. Overall, selecting the best preprinted label involves understanding your specific needs and the environment in which they will be used.

Comparison of Different Types of Preprinted Labels

Assessing Your Specific Labeling Needs and Applications

When selecting preprinted labels, understanding your labeling needs is crucial. Consider where and how you will use the labels. For instance, labels for shipping may need to withstand rough handling. In contrast, labels for product packaging should look appealing. The environment in which you use the labels can affect your choice. Extreme temperatures or moisture can lead to labels tearing or fading.

Think about the information that needs printing. Are barcodes or QR codes necessary? Some labels require specific font sizes for readability. This could impact the design and layout of your labels. Additionally, reflect on the volume of labels you’ll need. High-volume needs might benefit from larger rolls, while smaller quantities can be purchased in sheets.

Don’t forget about aesthetics. A label's design can influence customer perceptions. Using colors and fonts that align with your brand can be effective, but too much detail may confuse the reader. It’s often a balance to strike, and some trial and error may be involved. Consider testing different designs to see which works best for your audience.

Material and Durability Options for Preprinted Labels

Choosing the right material for preprinted labels is crucial. A study by the Label Industry Global Market Report indicates that over 40% of label failures are due to inadequate material selection. Common materials include paper, vinyl, and polyester, each with unique durability features. Paper labels are cost-effective but may not withstand moisture well. Vinyl offers greater resistance to fading and tearing. Polyester labels excel in harsh environments.

Durability is another key factor. Research shows that labels exposed to extreme temperatures or chemicals can degrade rapidly. For instance, paper labels may fade or peel under UV light. In contrast, synthetic materials endure better in demanding conditions. The choice of adhesive is vital too. Not all adhesives perform the same under different temperatures. A weak adhesive can lead to labels falling off, causing operational issues.

Consider the label's end use. If sustainability is a priority, recyclable materials might be ideal. However, they may come at a higher cost. According to industry estimates, companies using durable labels can reduce replacement costs by 30%. This can improve overall efficiency. Ultimately, assessing material options carefully reveals potential weaknesses in label selection.

Tips for Finding Reliable Suppliers and Quality Labels

When searching for reliable suppliers of preprinted labels, consider several critical factors. Industry reports indicate that about 45% of businesses face challenges in finding quality products. Quality labels are essential for branding. They ensure that your product stands out on the shelf, enhancing customer recognition and trust. Typically, labels should endure environmental conditions. For instance, labels used in freezers must withstand extreme temperatures without losing adherence or legibility.

Evaluating supplier options requires careful assessment. Look for suppliers with proven track records and strong customer reviews. A survey found that 30% of consumers switch suppliers due to poor service. Transparency is also crucial. Suppliers should provide samples and clear specifications regarding materials and printing technology. Many companies overlook this and end up disappointed with the final product.

Pricing is another key aspect but shouldn’t be the sole criterion. A cheaper label may save money upfront but cost more due to high failure rates. According to a recent study, businesses incur up to 20% additional costs from poor-quality labels. This highlights the importance of balancing cost and quality. Making an informed choice can significantly impact your business success.

Related Posts

-

Why Label Producers Are Essential for Streamlining Your Business Operations

-

Why Produce Labels Are Essential for Food Safety and Business Compliance in 2023

-

Why Choosing the Right Printers for Business Can Boost Your Productivity and Save Costs

-

2025 How to Choose the Best Label Making Machines for Your Needs

-

Top Trends in Bespoke Label Printing for 2025 You Need to Know

-

How to Create Stunning Bespoke Labels for Your Business or Projects