2026 How to Choose the Right Industrial Labels for Your Business Needs?

In today's competitive landscape, selecting the right industrial labels is crucial for business success. A report from Smithers Pira indicates that the global market for industrial labels is projected to reach $60 billion by 2026. This substantial growth highlights the need for companies to understand which labels best suit their operational demands.

Expert in labeling technologies, Dr. Emily Grantham, emphasizes the importance of thoughtful selection: “Choosing the right industrial labels can enhance efficiency and safety.” Her insights remind us that the process is not just about aesthetics; it involves practicality and compliance. Many companies struggle with label choices, often overlooking vital factors like durability, material, and barcoding options.

Moreover, the impact of incorrect labeling can be significant. Errors lead to waste, safety risks, and compliance issues. As businesses forge ahead, realizing the implications of their label choices is essential. With the right approach, companies can streamline operations and boost productivity through effective industrial labels.

Understanding the Different Types of Industrial Labels Available

Choosing the right industrial labels starts with understanding what options are available. There are various types of labels. Each type serves specific needs. For example, there are durable labels for tough environments. These are often weather-resistant and useful for outdoor settings. Then, there are barcode labels, essential for inventory management. They help streamline tracking products.

Additionally, you might consider safety labels. These highlight crucial information. They often contain warnings or instructions. Choosing the right label can be challenging. You need to evaluate your environment and requirements. For instance, a label that works well in a chilly warehouse may not last in a hot production area.

There's also the aspect of customization. Many industrial labels can be tailored for various applications. This includes size, color, and design. It's important to reflect on whether your labeling needs will change over time. Making the wrong choice could lead to wasted resources. Realizing your requirements early can save time and money in the long run.

Different Types of Industrial Labels and Their Uses

Key Factors to Consider When Choosing Industrial Labels

Choosing the right industrial labels is crucial for effective operations. Key factors include durability, material type, and application environment. Reports show that 40% of businesses face labeling issues due to poor material selection. The correct label must withstand environmental conditions, such as moisture, heat, or chemicals.

Tip: Always assess the specific environment where the labels will be used. For instance, if labels will be exposed to harsh chemicals, a chemical-resistant label is essential. Many businesses overlook this, leading to increased costs and wasted resources. Labeling errors can result in safety hazards and non-compliance.

Another factor is the visibility and legibility of labels. According to industry research, clear labels improve safety compliance by 30%. It's vital that labels are easy to read at a glance. This is often ignored during the design phase, resulting in confusion and potential accidents.

Tip: Consider using contrasting colors and bold fonts. This simple step can enhance readability significantly. Remember that a well-chosen label not only meets regulations but also boosts your brand’s professionalism. Neglecting this can tarnish your business reputation.

2026 How to Choose the Right Industrial Labels for Your Business Needs?

| Label Type | Material | Durability | Adhesive Type | Print Method | Application |

|---|---|---|---|---|---|

| Barcode Labels | Paper | Medium | Permanent | Thermal Transfer | Inventory Management |

| Asset Labels | Polyester | High | Strong | Digital Printing | Asset Tracking |

| Warning Labels | Vinyl | Durable | Permanent | Flexographic | Safety Compliance |

| Product Labels | Bopp | Medium | Removable | Litho Printing | Retail & Packaging |

Evaluating Label Durability and Suitability for Your Environment

When selecting industrial labels, evaluating their durability and suitability is crucial. The environment where labels will be used can greatly impact their longevity. For example, harsh environments with chemicals or extreme temperatures require robust labels that can withstand wear and tear. If labels fade or peel, it can lead to costly mistakes and inefficiencies.

Tips: Always consider the type of materials used in labels. Some materials resist chemicals better than others. Testing labels in actual work conditions can provide valuable insights. Regularly inspect label integrity—this helps in identifying any potential failures early.

Another aspect to consider is adhesion. Labels that don’t stick properly can cause significant issues. Ensuring the label adheres well to the surface is essential for operations. Don’t overlook the importance of printing quality—poor print can hinder readability. It’s worth considering feedback from employees who interact with these labels regularly. Their insights might reveal unexpected challenges or needs.

The Importance of Compliance and Regulations in Label Selection

When selecting industrial labels, compliance with regulations is crucial. Different industries have specific requirements. These guidelines ensure safety, reliability, and legal protection. Understanding these rules can feel overwhelming. The consequences of non-compliance can be severe. Fines and product recalls are just the beginning.

Consider the materials used for labels. Some environments require labels to withstand extreme temperatures or chemicals. Choose materials that meet these demands. This choice can prevent label failure and protect your brand's reputation. Often, businesses overlook the small print on label regulations. These details can make a big difference in efficacy.

Label clarity is another critical factor. Labels must be easy to read. Complex terms or small fonts can confuse customers or employees. Reflect on past experiences where unclear labeling caused issues. Strive for a balance between information and simplicity. Labels should convey essential details quickly. Each decision about labels is vital in maintaining compliance and enhancing safety.

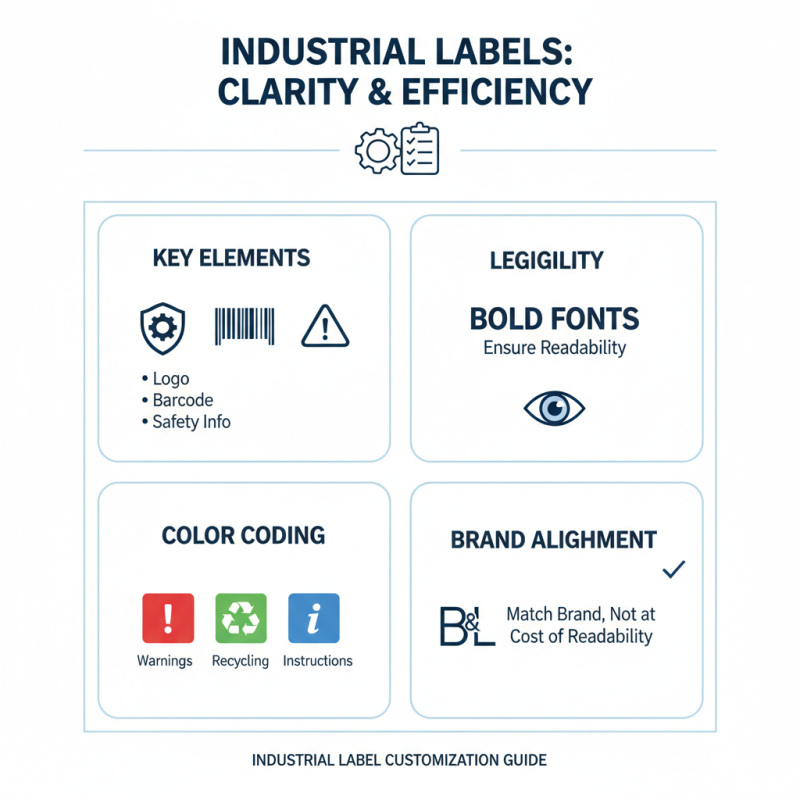

How to Customize Industrial Labels to Meet Your Business Needs

When customizing industrial labels, clarity is key. Labels should convey important information efficiently. Consider the key elements you want to include, like logos, barcodes, and safety instructions. Using bold fonts helps ensure legibility. Colors can signify specific messages, like warning or recycling information. Make sure the design aligns with your brand, but don’t sacrifice readability.

Durability is another crucial factor. Labels need to withstand harsh environments. Think about materials that resist moisture, chemicals, and UV exposure. Sometimes, a label meant for indoor use is chosen for outdoor applications. This can lead to premature wear and unclear messaging. Testing different materials may yield better long-term results.

The layout is also vital. Ensure ample space between elements to avoid clutter. Overly packed information can confuse workers. Use visuals where possible to break up text. When prototypes are created, gather feedback. This feedback might reveal overlooked details, highlighting areas for improvement. Adjusting based on real-world experiences is essential for effective labeling.

Related Posts

-

How to Create Stunning Bespoke Labels for Your Business or Projects

-

2025 How to Choose the Best Label Making Machines for Your Needs

-

Why Personalized Label Stickers Are Essential for Organizing Your Life

-

What is Manufacturing Labels? Understanding Industry Standards & Trends in 2023

-

How to Choose the Best Preprinted Labels for Your Needs?

-

Top Industrial Label Printers to Boost Your Business Efficiency and Productivity