2025 How to Choose the Best Label Making Machines for Your Needs

Choosing the right label making machines is a crucial decision for businesses and individuals alike, as these devices play an essential role in organizing, branding, and enhancing product presentation. In a market teeming with options, understanding the various features, types, and functionalities of label making machines is vital to ensuring that you select a model that meets your specific needs. Whether you're a small business owner looking to create custom labels for your products or a hobbyist aiming to organize your home with stylish tags, the right machine can make all the difference.

As technology continues to advance, label making machines have become more sophisticated yet user-friendly. From thermal printers to digital systems, these machines come equipped with a variety of capabilities, making it necessary to analyze what aspects are most important for your projects. In this guide, we will explore key factors to consider, including printing speed, label quality, connectivity options, and budget constraints, empowering you to make an informed choice. By understanding your requirements and the available options, you can find the perfect label making machine that not only fulfills your needs but also enhances your productivity and creativity.

Understanding the Different Types of Label Making Machines

When selecting the best label making machine for your needs, it is essential to understand the different types available in the market. Broadly, these machines can be categorized into three main types: desktop label printers, industrial label printers, and handheld label makers. Data from Smithers Pira indicates that the global market for label printing has seen a steady growth rate of approximately 3.5% per year, driven by the increased demand for customized and high-quality labels across various industries.

Desktop label printers are ideal for small to medium-sized businesses needing a cost-effective solution for printing labels quickly and efficiently. They typically offer a range of label sizes and styles, making them versatile for various applications. On the other hand, industrial label printers are built for high-volume production environments. According to a recent report by MarketsandMarkets, the industrial label printer market is projected to grow significantly, reaching $9.2 billion by 2025, as companies increasingly invest in automation and improved labeling efficiency. Lastly, handheld label makers provide portability and ease of use for on-the-go labeling, often appealing to smaller businesses or home users who require basic labeling functions without the need for extensive features.

Understanding the specific functionalities and target uses of each type will help you choose a label making machine that best suits your operational requirements and enhances productivity.

Key Features to Consider When Selecting a Label Maker

When selecting a label maker, several key features should be at the forefront of your decision-making process. First and foremost, consider the printing technology—thermal vs. inkjet. Thermal printers typically offer faster printing speeds and are more cost-effective in the long run, particularly for high-volume labeling tasks. On the other hand, inkjet printers may provide superior color quality for more vivid designs but can incur higher maintenance costs.

Another important feature is connectivity options. Modern label makers often support Bluetooth or Wi-Fi, allowing you to print directly from your smartphone or tablet, which enhances flexibility and convenience. Additionally, evaluate the software compatibility; a user-friendly app can significantly streamline your labeling process.

Lastly, assess the variety of label sizes and materials the machine can handle to ensure it meets your specific labeling needs, whether for home organization, business branding, or industrial applications.

Assessing Your Labeling Needs and Application Scenarios

When selecting the best label making machine for your needs, it’s crucial to assess your labeling requirements and the specific application scenarios.

Start by identifying the types of labels you will be creating—are they for products, shipping, or organizational purposes?

Understanding whether you need intricate designs, barcodes, or simple text will help you determine the features you require, such as print resolution and label size compatibility.

Consider the volume of labeling you anticipate. If you're producing labels in large quantities, a high-speed, commercial-grade machine may be necessary to keep up with demand. Conversely, for occasional home use, a compact and user-friendly model will suffice.

Additionally, think about the materials you'll be printing on—some machines excel with particular types of labels, such as those made of plastic or thermal paper.

By evaluating your specific labeling needs, you can streamline your options and choose a machine that enhances your productivity and meets your application demands effectively.

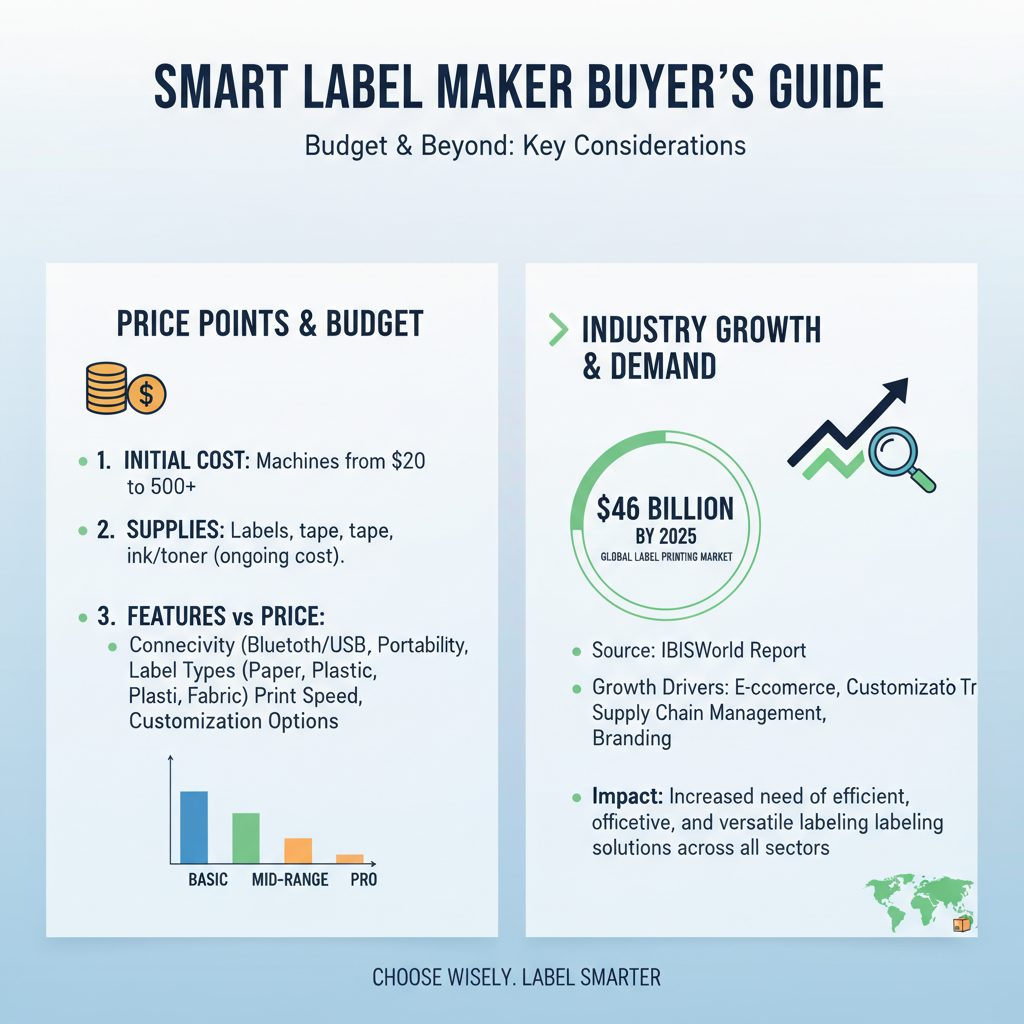

Comparing Price Points and Budget Considerations for Label Makers

When considering the purchase of a label-making machine, price points and budget considerations play a crucial role in the decision-making process. According to a report by IBISWorld, the label printing industry is expected to reach $46 billion by 2025, reflecting the growing demand for custom and high-quality labels across various sectors. This growth highlights the importance of selecting a label maker that fits within your financial parameters while meeting your production needs.

Basic label makers can range from $20 to $100, making them accessible for small businesses or home use. However, for professional-grade machines, prices can escalate to $1,000 or more, depending on the features offered, such as digital printing capabilities or high-volume efficiency. The Font Management Industry Report notes that investing in a mid-range label maker, typically priced between $300 and $600, often strikes a balance between affordability and performance, providing superior quality and durability for companies looking to enhance their branding. Understanding your specific needs and budget constraints is essential to make an informed choice that will support your labeling requirements effectively.

Exploring Brand Reputation and Customer Reviews for Label Machines

When choosing the best label making machines for your needs, it is crucial to consider brand reputation and customer reviews. A brand’s track record can often indicate the quality and reliability of its products. Well-established brands typically offer a range of label makers that have undergone rigorous testing and quality control processes. Therefore, it is beneficial to start your search by looking for brands that have built a solid reputation through consistent product performance and positive customer interactions.

Customer reviews serve as a valuable resource when evaluating label machines. These reviews provide firsthand experiences, highlighting both the strengths and weaknesses of specific models. Pay attention to recurring themes in reviews, such as ease of use, speed, and durability, which can give deeper insights into how a machine performs in a real-world setting. Engaging with customer feedback can guide you toward machines that align with your requirements, ensuring that your choice not only meets your needs but also comes with the assurance of positive user experiences.

Related Posts

-

2025 Top 5 Industrial Label Printing Solutions for Improved Efficiency

-

What is an Industrial Label Printer and How It Benefits Your Business

-

2025 Top Personalized Labels That Transform Your Organization Style

-

Why Label Producers Are Essential for Streamlining Your Business Operations

-

Why Produce Labels Are Essential for Food Safety and Business Compliance in 2023

-

Top 10 Label Stickers for Organizing Your Home and Office Efficiently