What is Industrial Label Printing? Benefits, Types, and Applications Explained

Industrial label printing plays a crucial role in various sectors. It encompasses producing durable, functional, and attractive labels for products. These labels carry important information. They help consumers identify products quickly. Many industries rely on high-quality labels to ensure compliance and brand recognition.

The benefits of industrial label printing are vast. It enhances product visibility and aids in inventory management. Companies can categorize goods efficiently. Additionally, industrial label printing offers customization. Businesses can choose materials, sizes, and colors to suit their needs. This flexibility is vital in a competitive market.

Applications of industrial label printing are widespread. From food packaging to pharmaceuticals, labels convey necessary information. They include ingredients, usage instructions, and safety warnings. Each industry demands specific label types. The unique requirements can challenge the printing process. Companies must continually refine their techniques to meet these demands. The evolution of technology also influences printing methods. New innovations can improve efficiency and quality, paving the way for better solutions.

What is Industrial Label Printing?

Industrial label printing refers to the production of high-quality labels for various applications. This printing method is crucial in sectors like manufacturing, logistics, and retail. According to a report by Smithers Pira, the global label market is expected to reach $50 billion by 2024. This signals a growing demand for effective labeling solutions.

The main advantage of industrial label printing is efficiency. High-speed printers produce labels quickly, which enhances productivity. Additionally, these labels are durable. They withstand harsh environments, including extreme temperatures and exposure to chemicals. However, not all solutions meet the required standards. Prints may fade or peel under stress, which can lead to significant operational issues.

Moreover, different types of labels cater to specific needs. For example, thermal transfer labels offer long-lasting prints. In contrast, direct thermal labels are suitable for short-term use. It's essential to choose wisely. Misalignment between label type and application can result in failures. Finally, staying updated on trends is vital. Industry shifts affect material choices and technology advancements. Embracing these changes can yield significant benefits.

The Benefits of Industrial Label Printing Solutions

Industrial label printing offers significant advantages across various sectors. These solutions improve efficiency, quality, and consistency. Labels produced in industrial settings can withstand harsh environments. They are often waterproof, tear-resistant, and can endure extreme temperatures. This durability is essential for industries like manufacturing, logistics, and food processing.

Customization is another key benefit. Companies can create tailored labels to fit specific needs. This includes unique sizes, colors, and printing methods. Such flexibility allows for effective branding and compliance with regulations. However, many businesses still struggle with integrating advanced label printing technologies. It’s vital to assess current systems to enhance productivity.

Moreover, the speed of industrial label printing can drastically reduce turnaround time. Products move faster from production to market. Yet, not every setup maximizes these benefits. Regular evaluations can identify areas for improvement. Embracing innovation in label printing can lead to better outcomes. Each step taken towards improvement creates new possibilities.

Industrial Label Printing: Types and Their Applications

Industrial label printing includes several types, each with its own market share and applications. This bar chart illustrates the distribution of market share among four major types of industrial labels: Thermal Transfer, Direct Thermal, Laser, and Inkjet. Understanding these shares can help businesses identify the most suitable labeling solutions for their needs.

Types of Industrial Labels and Their Specific Uses

Industrial labels come in various types, designed for specific uses across sectors like manufacturing, logistics, and retail. For instance, asset labels help track equipment. They often include barcodes for easy identification. Caution labels are crucial for safety, warning employees of hazards.

Another key type is shipping labels. These are vital for tracking parcels during transit. They typically feature addresses and barcodes, simplifying the shipping process. Meanwhile, product labels provide essential information about contents and usage. They often focus on compliance and marketing.

**Tip:** Choose the right label materials based on environmental conditions. For example, consider waterproof labels for outdoor use.

Labels might seem straightforward, yet their design requires thoughtful consideration. Choosing the wrong adhesive could lead to issues. Labels that peel off or fade can cause confusion and miscommunication. It's essential to test their durability in the intended environment.

**Tip:** Regularly review your labeling strategy. This ensures that labels remain effective and compliant with any updates in regulations or standards.

Common Applications of Industrial Label Printing in Various Industries

Industrial label printing plays a crucial role in various sectors. It enhances product identification and streamlines operations. Common applications include packaging, manufacturing, and logistics. Labels are vital for tracking inventory and ensuring compliance. In the food industry, labels provide essential information about ingredients and safety.

Tips: Consider using eco-friendly materials for labels. This not only helps the environment but also appeals to environmentally-conscious consumers.

Healthcare relies heavily on accurate labeling. Labels on medications help prevent errors. Patient information labels ensure safety and proper handling. Neglecting this aspect can lead to serious consequences. Companies must regularly review their labeling processes.

Tips: Regular audits of label quality can help avoid mistakes. Engage staff in training sessions to emphasize the importance of accurate labeling.

In the retail sector, labels enhance customer experience. They guide shoppers in making informed choices. Clear pricing and promotional labels influence purchasing decisions. However, the design must be user-friendly. Complicated graphics can confuse customers rather than attract them.

Key Technologies and Techniques Used in Industrial Label Printing

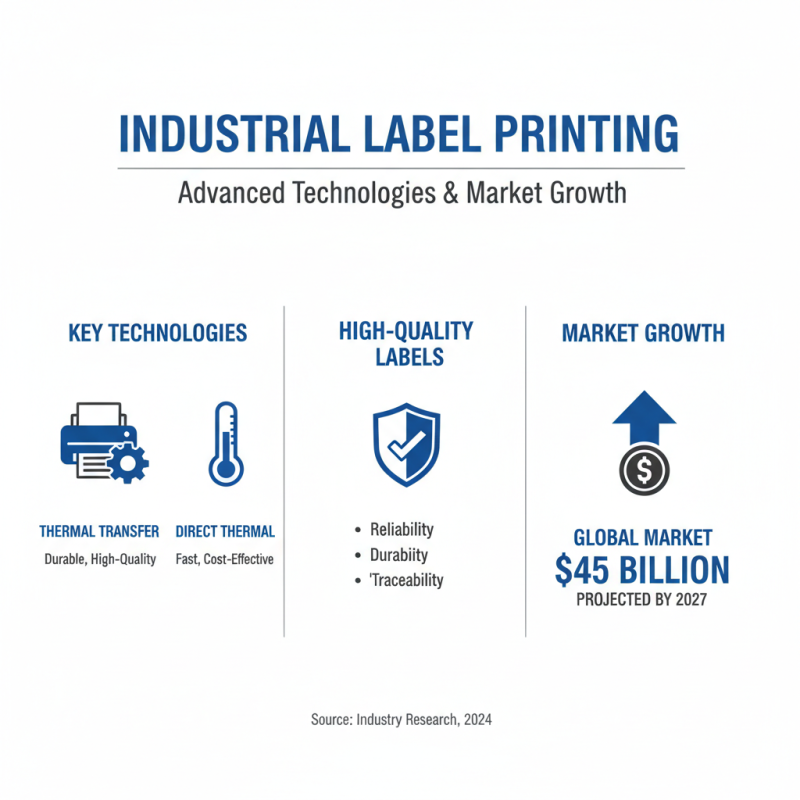

Industrial label printing employs advanced technologies to create high-quality labels. Key techniques include thermal transfer and direct thermal printing. Research indicates that the global industrial label market is projected to reach $45 billion by 2027, demonstrating its significant growth.

Thermal transfer printing uses heat to transfer ink from a ribbon to the label. This method offers durability and is resistant to fading. Conversely, direct thermal printing relies on heat-activated materials. This technique produces clear images but is more susceptible to environmental factors. Companies often face challenges in choosing the right method for their needs.

Digital printing is gaining traction due to its speed and flexibility. Companies can produce custom labels in short runs without significant setup costs. Specialty inks, such as UV and eco-solvent, are also evolving. However, inconsistency in quality can be an ongoing issue. A study notes that 38% of companies report difficulties with label adhesion under varying conditions. This highlights the need for ongoing innovation and quality control in the industry.

Related Posts

-

2025 Top 5 Industrial Label Printing Solutions for Improved Efficiency

-

What is an Industrial Label Printer and How It Benefits Your Business

-

Why Are Electrical Labels Essential for Safe Wiring and Compliance

-

Why Personalized Label Stickers Are Essential for Organizing Your Life

-

Top 10 Label Making Machines for Easy and Efficient Label Creation

-

Why Label Printers Are Essential for Your Business Efficiency and Organization