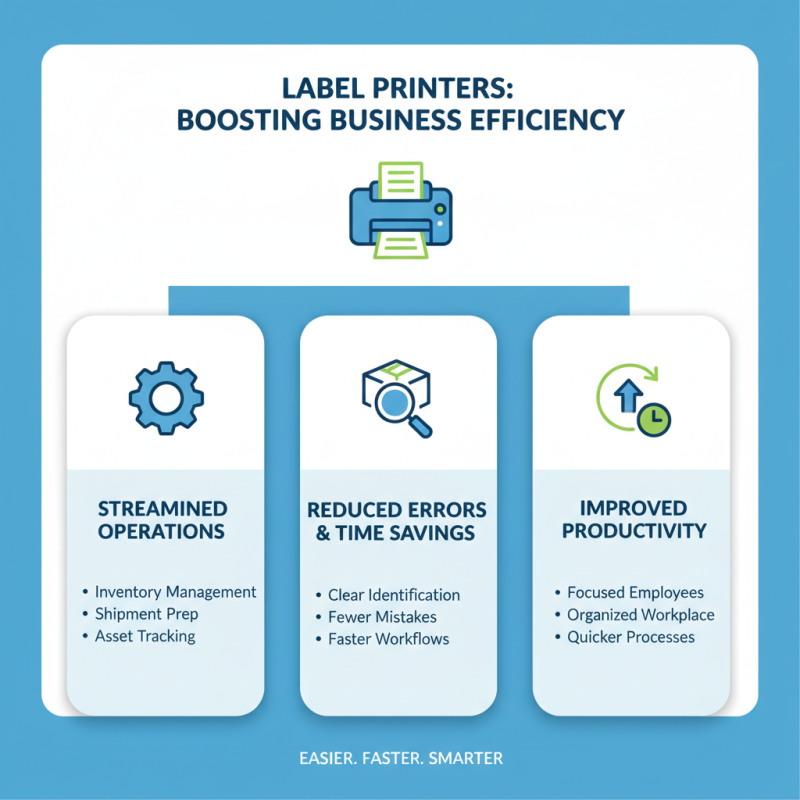

Why Label Printers Are Essential for Your Business Efficiency and Organization

In today's fast-paced business environment, efficiency and organization are paramount to success. One of the most effective tools that can streamline operations and enhance productivity is the use of label printers. These devices not only simplify the process of labeling products and inventory but also contribute to maintaining clarity and precision in various business functions. By implementing label printers, companies can reduce errors, save time, and improve overall workflow.

Label printers are versatile tools that cater to diverse industries, from retail to logistics, by enabling businesses to create high-quality, customizable labels on demand. This capability eliminates the need for pre-printed labels, allowing for greater flexibility and reducing waste. Furthermore, the organized labeling systems foster better inventory management, which is crucial for timely fulfillment of customer orders and effective communication within teams.

In this article, we will delve into the multifaceted benefits of label printers, exploring how they can significantly enhance business efficiency and organization. By understanding their impact, businesses can make informed decisions about integrating these essential tools into their daily operations, ultimately driving growth and improving service delivery.

Importance of Label Printers for Streamlined Operations

Label printers play a crucial role in enhancing the operational efficiency and organization within any business. By providing clear and accurate labeling solutions, they help streamline processes across various departments. From inventory management to shipment preparation, having the right labels ensures that items are easily identifiable, which reduces errors and saves time. This efficiency translates to improved productivity, allowing employees to focus on their core responsibilities rather than spending time deciphering unlabeled or incorrectly labeled items.

**Tips for Implementing a Label Printing System:**

- Invest in versatile label printers that can handle different sizes and types of labels based on your business needs. This adaptability allows you to customize your labels for various products or purposes.

- Integrate your labeling system with existing inventory management software. This will facilitate real-time updates and minimize the chances of discrepancies during stocktaking or order fulfillment.

- Regularly update your label designs to ensure clarity and compliance with any industry regulations. This proactive approach helps maintain organization and prevents potential issues related to labeling errors.

Incorporating label printers into your daily operations not only simplifies tasks but also fosters a culture of organization. The time saved on manual labeling can be redirected towards more strategic initiatives, enhancing overall business performance. By prioritizing effective labeling solutions, businesses position themselves for sustained growth and efficiency.

Enhancing Inventory Management with Label Printers

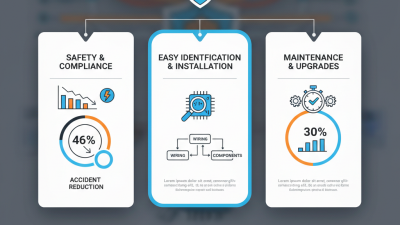

Label printers play a crucial role in enhancing inventory management, making them indispensable for businesses seeking improved efficiency and organization. According to a report by a leading research firm, efficient labeling systems can reduce inventory discrepancies by over 30%. This statistic highlights how proper labeling can streamline tracking processes, ultimately leading to better stock visibility and reduced costs associated with overstocking or stockouts.

Implementing a labeling solution can also transform how businesses handle product information. Many organizations are now utilizing barcodes and QR codes to facilitate quick scanning, which accelerates the inventory checking process. In fact, studies suggest that businesses using advanced labeling techniques can cut down time spent on inventory audits by as much as 50%. This efficiency not only boosts productivity but also enhances customer service, as accurate inventory data leads to improved order fulfillment rates.

Tips: When integrating label printers into your inventory management system, consider training your staff on best practices for label application and scanning. This can significantly reduce errors. Additionally, regularly updating and maintaining your labeling software ensures that your inventory records remain accurate and reliable, which is key for optimal operations.

Boosting Workplace Organization through Effective Labeling

Effective labeling is a cornerstone of workplace organization and can significantly enhance business efficiency. When everything is clearly labeled, employees can quickly find the materials they need, reducing time wasted on searching for items. This streamlined process not only boosts productivity but also fosters a more organized environment, minimizing clutter and confusion. By implementing a robust labeling system, businesses can create a workspace that promotes focus and efficiency.

**Tip 1:** Use color-coded labels to categorize items by department or function. This visual cue will enable staff to locate supplies with ease and ensure that everything has its designated place.

Moreover, labeling equipment, files, and storage areas contributes to standardization across the workplace. Employees will know the exact parameters for organizing and retrieving items, leading to consistent practices that enhance communication and collaboration. This consistency is essential for maintaining a professional atmosphere and ensuring a seamless workflow.

**Tip 2:** Regularly review and update your labeling system to keep it relevant. Engage your team in this process to ensure everyone’s input is valued, which can lead to an even more efficient organization strategy.

Incorporating effective labeling not only simplifies operations but also empowers employees to take ownership of their workspaces, resulting in a more motivated and engaged team.

Cost Savings and Efficiency Gains from Label Printers

Label printers play a pivotal role in enhancing operational effectiveness and cutting costs for businesses across various sectors. By automating the labeling process, companies can significantly reduce the time and labor costs associated with manual labeling. This efficiency not only streamlines workflows but also minimizes the risk of errors that often come with hand-written or manually printed labels. The ability to create high-quality labels quickly allows businesses to meet demands and deadlines, ultimately contributing to a smoother operational flow.

In addition to the time savings, the long-term cost benefits of investing in label printers are substantial. Businesses can save on materials by using label printers that support different formats and sizes, eliminating the need for multiple labeling solutions. Furthermore, having an in-house labeling system can reduce reliance on external vendors, which often comes with shipping and handling fees. The flexibility in printing labels on-demand also means that companies can quickly adapt to changes in inventory or product lines without incurring additional costs. Overall, the integration of label printers into daily operations can lead to significant improvements in both productivity and cost management.

Impact of Label Printers on Business Efficiency and Cost Savings

Choosing the Right Label Printer for Your Business Needs

When selecting a label printer for your business needs, understanding the specific requirements of your operations is paramount. According to a recent report by the Freedonia Group, the global market for label printers is expected to reach $5.5 billion by 2024, reflecting a growing demand driven by various industries such as retail, logistics, and healthcare. Identifying the right label printer involves evaluating factors such as print speed, resolution, and the types of labels required, whether they be thermal, inkjet, or laser.

Furthermore, considering the volume of labels your business will produce can significantly influence your choice. For instance, businesses producing more than 100 labels per day may benefit from high-speed printers that offer durability and efficiency. A study by Smithers Pira highlights that businesses can reduce operational costs by up to 30% when utilizing automated labeling systems versus manual processes.

This efficiency not only streamlines workflow but also enhances accuracy, critical in sectors where label precision is crucial, such as pharmaceuticals and food packaging. Making an informed decision on selecting a label printer tailored to your business requirements can lead to improved productivity and organization, ultimately supporting your overall operational success.

Related Posts

-

What is an Industrial Label Printer and How It Benefits Your Business

-

Top 10 Label Stickers for Organizing Your Home and Office Efficiently

-

2025 Top Personalized Labels That Transform Your Organization Style

-

Why Produce Labels Are Essential for Food Safety and Business Compliance in 2023

-

Why Are Electrical Labels Essential for Safe Wiring and Compliance

-

What is Manufacturing Labels? Understanding Industry Standards & Trends in 2023