Top Industrial Label Printers to Boost Your Business Efficiency and Productivity

In today's fast-paced business environment, efficiency and productivity are essential for staying competitive. One crucial component that can significantly enhance these aspects is the use of industrial label printers. These specialized devices are designed to streamline the labeling process, allowing businesses to efficiently manage their inventory, logistics, and compliance requirements. By investing in high-quality industrial label printers, companies can reduce errors, improve workflow, and ultimately save valuable time and resources.

Industrial label printers come equipped with advanced features that cater to the unique needs of various industries. Whether it's high-volume production, durable labeling for challenging environments, or customizable options for branding, these printers provide tailored solutions that enhance operational effectiveness. Furthermore, the integration of technology in modern industrial label printers, such as connectivity with inventory management systems, offers unparalleled convenience and accuracy.

As businesses strive for more sustainable practices and cost-effective operations, the role of industrial label printers becomes increasingly vital. By adopting these printing solutions, organizations can not only optimize their processes but also strengthen their commitment to quality and customer satisfaction. Embracing the power of industrial label printers is a strategic move that can lay the foundation for long-term success and growth in a competitive market landscape.

Types of Industrial Label Printers Available in the Market

When it comes to enhancing business efficiency and productivity, choosing the right industrial label printer is crucial. There are several types of industrial label printers currently available in the market, each designed to cater to specific needs. The most common types include thermal transfer printers, direct thermal printers, and inkjet printers. Thermal transfer printers offer durability and high-quality prints for labels that need to withstand harsh environments, while direct thermal printers are ideal for short-term labeling needs. Inkjet printers, on the other hand, provide versatility in terms of color options and can accommodate a variety of materials.

Tips: When selecting an industrial label printer, consider your specific labeling needs, such as the volume of labels required and the types of materials you'll be printing on. It's also essential to evaluate the printer's speed and connectivity options for seamless integration into your existing workflow.

Additionally, specialized printers designed for particular industries, such as food, healthcare, or logistics, can further enhance productivity by complying with industry-specific regulations. These printers often come with features tailored to the requirements of labeling in those sectors, ensuring that labels are not only compliant but also optimized for performance.

Tips: Always test a label printer with your typical labels before making a purchase. This will help ensure that it meets your quality standards and that it can handle the specific label sizes and types you plan to use.

Key Features to Consider When Selecting a Label Printer

When selecting a label printer to enhance business efficiency and productivity, several key features should be carefully evaluated. First and foremost, print speed and resolution are critical; a printer that offers high-speed printing without compromising quality can streamline operations significantly. Businesses that require large volumes of labels will benefit from a model that can produce clear, professional-looking labels quickly, reducing wait times and improving workflow.

Another important consideration is connectivity options. A label printer that supports various connectivity methods, such as USB, Ethernet, and wireless capabilities, allows for greater flexibility in various working environments. This feature enables multiple users to access the printer from different devices, enhancing collaboration and efficiency. Additionally, robust software compatibility should not be overlooked, as an integrated solution allows users to easily design, print, and manage labels with minimal hassle, maximizing overall productivity.

Benefits of Using Industrial Label Printers for Business Operations

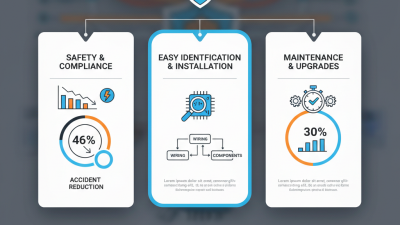

In today’s fast-paced business environment, efficiency and productivity are crucial for success, and industrial label printers have emerged as key tools to enhance these aspects of operations. According to a report by Smithers Pira, the global market for industrial label inks alone is projected to reach over $18 billion by 2024, indicating significant growth as companies increasingly recognize the importance of high-quality labeling solutions. Industrial label printers streamline processes by allowing businesses to print labels on-demand, drastically reducing the time spent preparing shipments and managing inventory.

The benefits of utilizing industrial label printers extend beyond mere efficiency; they also improve accuracy and reduce errors in labeling. A recent study by the Freedonia Group found that businesses that implement advanced labeling systems can decrease mislabeling rates by 30%, which not only minimizes waste but also enhances customer satisfaction through accurate order fulfillment. Furthermore, automated labeling systems help to maintain compliance with regulatory standards, ensuring that products are correctly labeled according to industry regulations, thus avoiding potential penalties and enhancing brand reliability.

When integrated into a comprehensive operational workflow, industrial label printers can also support data management systems, enabling better tracking and analytics. This connectivity allows companies to analyze inventory levels, supply chain efficiencies, and customer preferences, fostering a data-driven approach to decision-making. In an age where timely information is paramount, the adoption of industrial label printers serves as a fundamental element in driving business efficiency and maximizing productivity.

Comparative Analysis of Leading Industrial Label Printer Brands

In the competitive landscape of industrial labeling, the efficiency and productivity of businesses are greatly influenced by the choice of label printers. A comparative analysis of leading industrial label printer brands reveals significant variations in performance metrics such as print speed, resolution, and durability. According to industry reports, printers with a speed range of 6 inches per second to 12 inches per second can drastically reduce production time, allowing businesses to meet tight deadlines and increase throughput. Moreover, high-resolution capabilities ranging from 200 to 600 dpi ensure that labels are produced with clear, accurate information, minimizing errors in product labeling.

Additionally, the longevity and reliability of label printers are paramount in industrial settings. Recent data suggests that models with robust construction and advanced thermal technology can reduce maintenance costs by up to 30%, translating to increased operational uptime. Businesses that prioritize this reliability not only save on repair expenses but also benefit from improved workforce efficiency, as employees spend less time troubleshooting and more time focused on core production tasks. Moreover, the integration of user-friendly interfaces in newer models has been shown to enhance productivity by reducing training time for staff, enabling quicker adaptation to new systems. This comprehensive analysis highlights the critical criteria for choosing industrial label printers that align with business productivity goals.

Comparison of Industrial Label Printer Features

Tips for Maintaining and Optimizing Label Printing for Efficiency

Maintaining and optimizing label printing can significantly enhance business efficiency and productivity. One key aspect is regular maintenance of the printers. This involves routine cleaning and inspections to ensure that the printing heads are free from debris and the ink cartridges are filled appropriately. Establishing a maintenance schedule not only prolongs the printer's lifespan but also minimizes unexpected downtimes that can disrupt workflow.

In addition to maintenance, optimizing the design and workflow of label printing processes is crucial. Businesses should invest in professional design software that allows for easy customization of labels to meet specific needs without compromising quality. Moreover, improving the organization of label storage and retrieval systems can streamline the printing process. By implementing a systematic approach to label management, companies can reduce the time spent searching for materials or making adjustments, ultimately leading to higher productivity levels.

Related Posts

-

What is an Industrial Label Printer and How It Benefits Your Business

-

Why Label Printers Are Essential for Your Business Efficiency and Organization

-

Why Are Electrical Labels Essential for Safe Wiring and Compliance

-

How to Create Stunning Bespoke Labels for Your Business or Projects

-

Why Choosing the Right Printers for Business Can Boost Your Productivity and Save Costs

-

How to Effectively Label It Labels for Better Organization and Clarity