Top 10 Tips for Printing Labels: Optimize Your Labeling Process Today!

In the fast-paced world of business, efficient labeling is more essential than ever. According to renowned expert in the field of printing labels, Dr. Emily Carter, "The way we approach printing labels can significantly impact not just our operational efficiency, but also our customer satisfaction." As organizations strive to streamline their processes, optimizing the labeling workflow becomes a critical factor in ensuring smooth operations and effective communication.

In this guide, we delve into the top 10 tips for improving your printing labels process, designed to help you navigate the complexities of labeling in today's dynamic environment. From selecting the right materials to understanding printer settings, these insights will empower you to enhance your labeling strategy and avoid common pitfalls. By implementing these best practices, businesses can not only reduce costs but also elevate their brand presentation through high-quality labels that convey professionalism and clarity.

Embracing these techniques can transform the way you manage your printing labels, making it a seamless part of your overall business strategy. Get ready to optimize your approach and discover the potential that well-executed labeling holds for your organization.

Understanding Different Types of Labels for Your Needs

When it comes to optimizing your labeling process, understanding the different types of labels available is crucial for meeting your specific needs. From paper labels to synthetic materials, the choice of label can significantly impact both the appearance and durability of your products. According to a recent industry report, the global label market is projected to grow at a CAGR of 4.5% through 2027, emphasizing the increasing importance of effective labeling in various sectors. Selecting the right label type ensures that your products are compliant with regulations and meet the expectations of your target audience.

One pivotal tip for improvement is to assess the environmental conditions that your labels will face. For instance, if your labels will be exposed to moisture or extreme temperatures, consider using waterproof or thermal-resistant labels to maintain legibility and adherence. Additionally, employing high-quality inks and adhesives can significantly enhance the longevity of your labels under such conditions.

Another tip is to utilize digital printing technology, which allows for greater flexibility and customization in label design. A study indicated that companies leveraging digital printing for labels have witnessed a 30% increase in production efficiency, enabling them to reduce costs and time without sacrificing quality. By incorporating these insights into your labeling strategy, you can enhance not only the effectiveness of your labels but also streamline your overall labeling process.

Choosing the Right Printer for Efficient Label Production

When it comes to optimizing your label production process, choosing the right printer is crucial. According to a study by Smithers Pira, the global digital label market is expected to reach $23 billion by 2024, driven by the demand for customized and variable data printing. This surge emphasizes the importance of selecting printers that not only meet the demands of volume but also deliver high-quality output. For small to medium-sized businesses, inkjet printers have become increasingly popular due to their versatility and ability to produce vibrant colors at a lower initial investment. Meanwhile, industrial-scale operations may benefit from thermal transfer printers, which provide faster speeds and lower cost per label over time.

Furthermore, understanding the specific requirements of your labeling projects can greatly influence your printer choice. Data from AIDC 2021 indicates that the average cost of misprinting labels can exceed $5,000 annually for small businesses, highlighting the impact of selecting a printer that ensures precise labeling without errors. Businesses should consider factors such as print speed, durability of labels, and compatibility with various label materials when making their decision. This tailored approach not only streamlines production but also enhances overall efficiency, allowing companies to adapt swiftly to market demands and consumer preferences.

Top 10 Tips for Printing Labels: Optimize Your Labeling Process Today!

| Tip | Description | Best Printer Type | Label Material |

|---|---|---|---|

| 1. Choose the Right Printer | Select a printer that’s compatible with the label material you're using. | Inkjet or Laser Printer | Paper, Vinyl |

| 2. Assess Volume Needs | Determine how many labels you need to print and how often to choose an efficient solution. | High-Speed Printer | Durable Paper |

| 3. Select Quality Labels | Invest in high-quality labels to ensure durability and visibility. | Thermal Transfer Printer | Polyester, Polypropylene |

| 4. Use Design Software | Utilize software to create or modify label designs to fit needs. | Compatible Printers | Various materials |

| 5. Optimize Printer Settings | Adjust printer settings for best print quality depending on the label material. | Specific Printer Brand | Choose accordingly |

| 6. Test Prints | Always do a test print before executing a full batch. | Any type | Standard Paper |

| 7. Maintain Equipment | Regular maintenance of printers ensures longevity and efficiency. | All Printers | Not applicable |

| 8. Keep Labels Clear | Ensure that the text and images on the label are legible. | Any type | High-quality paper |

| 9. Utilize Label Templates | Use templates to streamline design and printing processes. | Inkjet or Laser Printer | Standard or Custom Labels |

| 10. Review Before Printing | Always double-check for errors in the design and information. | Any Printer | Any material |

Design Best Practices for Eye-Catching Labels

When it comes to designing labels that stand out, adhering to best practices is crucial. According to a recent study by the Label & Narrow Web magazine, approximately 70% of consumers consider packaging design as a significant factor in their purchasing decisions. This statistic highlights the importance of creating eye-catching labels that not only convey essential information but also attract potential customers. Utilizing vibrant colors and high-quality graphics can evoke emotions and enhance brand recognition, making the product more memorable.

Moreover, clarity is key in label design. Research by the Packaging Association indicates that 60% of consumers prefer simple, easy-to-read labels, which means that less is often more when it comes to the amount of information displayed. Opting for clear fonts, concise wording, and strategic placement of images can improve the overall effectiveness of the label. Incorporating elements such as white space can also help to prevent the label from appearing cluttered, allowing the essential information to shine through while maintaining visual appeal. Implementing these design best practices can significantly optimize the labeling process and boost product visibility in a crowded market.

Essential Software for Simplifying Your Labeling Process

In today’s fast-paced business environment, optimizing the labeling process is crucial for efficiency and accuracy. The right software tools can transform a cumbersome labeling task into a streamlined operation. According to a recent report by the Label Manufacturers Institute, over 70% of companies that implemented automated labeling software reported a significant improvement in productivity. This underscores the importance of choosing essential software that integrates seamlessly with existing systems, enabling users to design, print, and manage labels with ease.

Moreover, the adoption of advanced software solutions also contributes to error reduction. A study by the National Association of Printing Leaders indicated that manual labeling processes lead to a 25% higher error rate compared to automated solutions. By leveraging software that offers features like barcode generation, template customization, and real-time inventory tracking, businesses can enhance their labeling accuracy and ensure compliance with industry standards. Investing in the right labeling software not only aids in operational efficiency but also positively impacts overall supply chain management, making it an indispensable component for modern businesses.

Top 10 Label Printing Software Features

Tips for Organizing and Storing Printed Labels Effectively

When it comes to the effective organization and storage of printed labels, a strategic approach is essential. First and foremost, categorizing labels by type, size, or purpose can streamline the retrieval process. Use clear, labeled bins or folders to keep similar labels together, which can save time during busy operations. For instance, having separate sections for shipping labels, product tags, or inventory markers reduces the chances of confusion and ensures that you can quickly access the labels you need.

Moreover, consider the environmental conditions in which labels are stored. Labels are often made from materials that can degrade over time if exposed to excessive heat, humidity, or light. Therefore, it’s advisable to store them in a cool, dry place away from direct sunlight. Additionally, digital inventory management can greatly enhance your labeling efficiency. By keeping a digital record of your label stock and usage, you can easily track what you have on hand and when it’s time to reorder. This digitization not only keeps you organized but also helps in maintaining optimal stock levels to avoid interruptions in your labeling process.

Related Posts

-

2025 How to Choose the Best Label Making Machines for Your Needs

-

Why Choosing the Right Printers for Business Can Boost Your Productivity and Save Costs

-

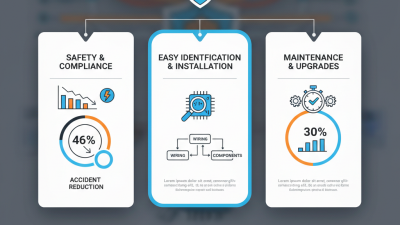

Why Are Electrical Labels Essential for Safe Wiring and Compliance

-

2025 Top 5 Industrial Label Printing Solutions for Improved Efficiency

-

Why Label Producers Are Essential for Streamlining Your Business Operations

-

How to Create Bespoke Labels: A Step-by-Step Guide for Unique Branding